Products related to my wastewater treatment system

Products related to my wastewater treatment system

Hello everyone! I am a quality management

professional at a manufacturer specializing in inverters and servo motors. With

15 years of experience in this industry, I’ve

encountered and analyzed numerous product failures. Today, I’d like to share my insights with you.

First of all, many private enterprises in

China do not place enough emphasis on the actual operation of quality

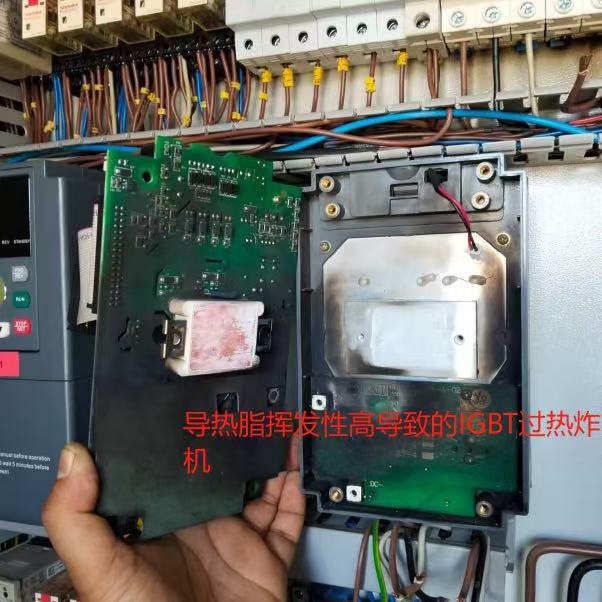

management systems. As a result, when inverters and servo motors experience

failures, such as explosions, the common response is to attribute the issue to

client-side overcurrent or overvoltage, without identifying the true root

cause. This lack of understanding leads to repeated unresolved issues,

ultimately resulting in customer loss.

At Shanghai Jieenlu Electronic TechnologyCo., Ltd., we specialize in producing inverters and servo motors. From the

inception of our company, we have prioritized the establishment and

implementation of a robust quality management system. We have developed and

strictly enforced quality assurance process flows for every project. In the

inverter industry, we have achieved a PPM (parts per million) defect rate of

200, approaching the standards of the automotive industry.

Key Quality Control Measures:

1. Material Preparation:

Before production begins, it is critical to

organize the BOM (Bill of Materials) for inverters and servo motors. Ensure

that the specifications of every electronic component and accessory meet the

required standards, guaranteeing product longevity.

2. Thermal Management:

• Confirm that electronic

components can operate within their designed temperature ranges.

• Proper management of

reflow and wave soldering temperatures.

By paying close attention to these details,

even if an explosion occurs, it is possible to trace the issue back to its

source, identify the root cause, and implement continuous improvements. This

enables us to gradually enhance product quality and achieve low failure rates

and PPM levels.

Our AGD310, AGD300, and AGD310 series

products, ranging from 0.5KW, 0.75KW, 1KW, 1.5KW, 2.2KW, to 50KW, undergo

rigorous design validation and assessment. Only after passing all tests are

they introduced to the market, where they have gained an excellent reputation.

At Shanghai Jieenlu Electronic TechnologyCo., Ltd., we are dedicated to providing top-quality inverters and servo

motors, adhering to the principle of serving our customers and striving to

become a premium cooperative supplier in China.

For collaboration inquiries, please contact

us:

Company website:

https://www.sh-jieenlu.com/

WhatsApp: +15001775783