The maintenance of the frequency converter drive circuit

The maintenance of the frequency converter drive circuit

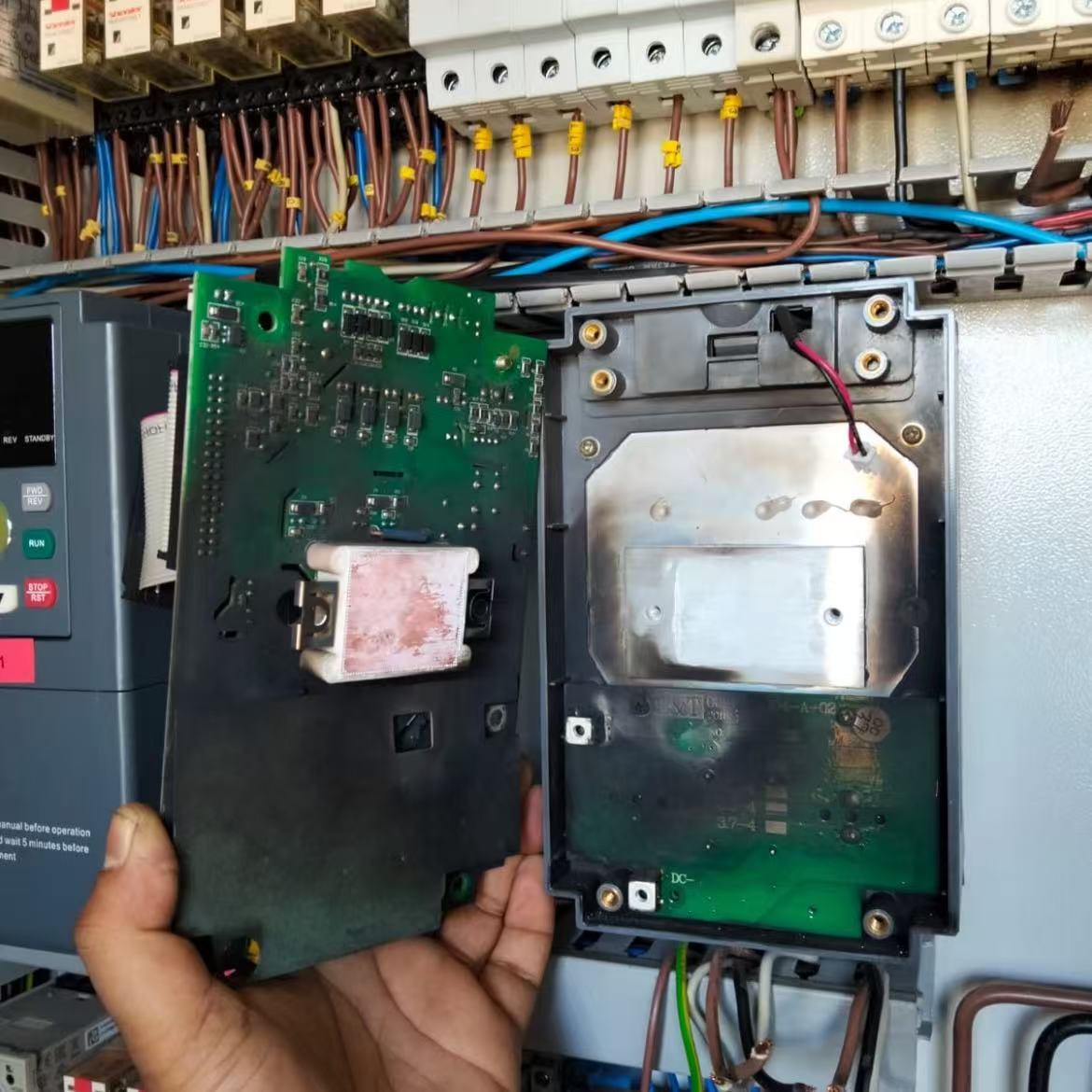

Most faults in frequency converters occur in the drive circuit, which is closely related to the power module. Abnormalities in the drive circuit not only manifest as the inability of the inverter module to function properly but may also lead to damage or even direct explosion of the inverter power module during the power-on process.

The maintenance of the drive circuit of a frequency converter mainly includes fault detection, cause analysis, and repair procedures.

Products related to my wastewater treatment system

Firstly, when

maintaining the drive circuit of a frequency converter, fault detection is

required. This typically involves using tools such as a multimeter to test

parameters like resistance and voltage in the drive circuit to determine if

there are any abnormalities. For example, the resistance of the drive pins of

the IGBT module can be measured, and the voltages of the six drive circuits can

be compared to see if they are the same, thereby providing an initial

assessment of whether the drive circuit is intact.

Secondly, it is

necessary to analyze the causes of the fault. There can be many reasons for

faults in the drive circuit of a frequency converter, such as insufficient

capacitance or loss of capacitance in the filter capacitor, damage to

components in the power circuit, aging of the drive circuit, etc. Therefore,

during the maintenance process, it is essential to carefully analyze the causes

of the fault and take corresponding repair measures based on the actual

situation. For example, when it is found that the filter capacitor is bulging

or has insufficient capacitance, it needs to be replaced with a new one

promptly.

Finally,

corresponding repair steps should be taken based on the identified fault

causes. These steps may include replacing damaged components, repairing circuit

connections, adjusting circuit parameters, etc. During the repair process, it

is important to prioritize safety operations to avoid hazards such as electric

shock. Additionally, necessary tests should be conducted to ensure that the

repaired frequency converter can operate normally. For example, after replacing

components, no-load and load tests should be performed to check if the output

voltage and current are balanced and normal.

In summary, the inverter power module in a frequency converter is a vulnerable component. When the inverter power module is damaged due to breakdown, the drive circuit may also be damaged by a strong electrical shock. Therefore, after the inverter power module is damaged, the drive circuit should be thoroughly inspected. It is important to determine whether the module damage was caused by quality issues with the module itself, a short circuit in the load, or problems with the drive circuit. Special attention should be paid to safety when replacing the IGBT in the inverter power module. The replacement must only be carried out after thoroughly confirming that the drive circuit is functioning normally. To avoid the risk of the IGBT module being destroyed during installation or testing, it is crucial to ensure that there are no faults in the drive circuit.