Solutions for OC and OV Faults in Frequency Converters

What is the OC fault in a frequency converter?

Products related to my wastewater treatment system

The OC fault in a

frequency converter refers to an over-current fault.

OC stands

for Over Current, indicating that the output current of the frequency converter

has exceeded its preset over-current detection threshold1. In the frequency converter manual, OC is

usually clearly labeled as an over-current fault, along with other related

faults such as short-circuit fault (SC). The OC fault is one of the most

frequent alarm phenomena in frequency converters, with complex and diverse

causes, mainly including excessive load, overly short acceleration/deceleration

time settings, damage to the inverter module, damage to the drive circuit, etc.12. When an over-current fault occurs in the

frequency converter, it is necessary to identify and resolve it promptly and

accurately to ensure the continuity and efficiency of the production line and

avoid greater economic losses.

What are the solutions to the OC fault of the

frequency converter? The solutions to the OC fault of the frequency converter

mainly include checking the load condition, adjusting the acceleration and

deceleration time, checking the torque boost amount, limiting the current and

torque, considering increasing the power of the frequency converter, and

checking the internal components of the frequency converter, etc.

- Checking the Load

Condition:

- Confirm whether the load is within the carrying

capacity of the frequency converter. If the load is too heavy, it needs

to be reduced or a more powerful frequency converter should be replaced12.

- Check whether the motor is operating normally

and whether the motor cable is too long or improperly selected, causing

excessive output leakage current. If there are faults, repairs or

replacements are required4.

- Adjusting the

Acceleration and Deceleration Time:

- Confirm whether the acceleration and

deceleration time is set too short, and appropriately extend it to avoid

excessive current13.

- Checking the Torque

Boost Amount:

- Check whether the torque boost amount is too

large. If it is, reduce the corresponding value of the function code and

observe whether the current decreases without loss of speed3.

- Limiting the Current

and Torque:

- Set the current limit and torque limit to the

effective state to prevent overcurrent situations3.

- Considering

Increasing the Power of the Frequency Converter:

- If the load demand is large, consider

increasing the power of the frequency converter to meet the high current

demand13.

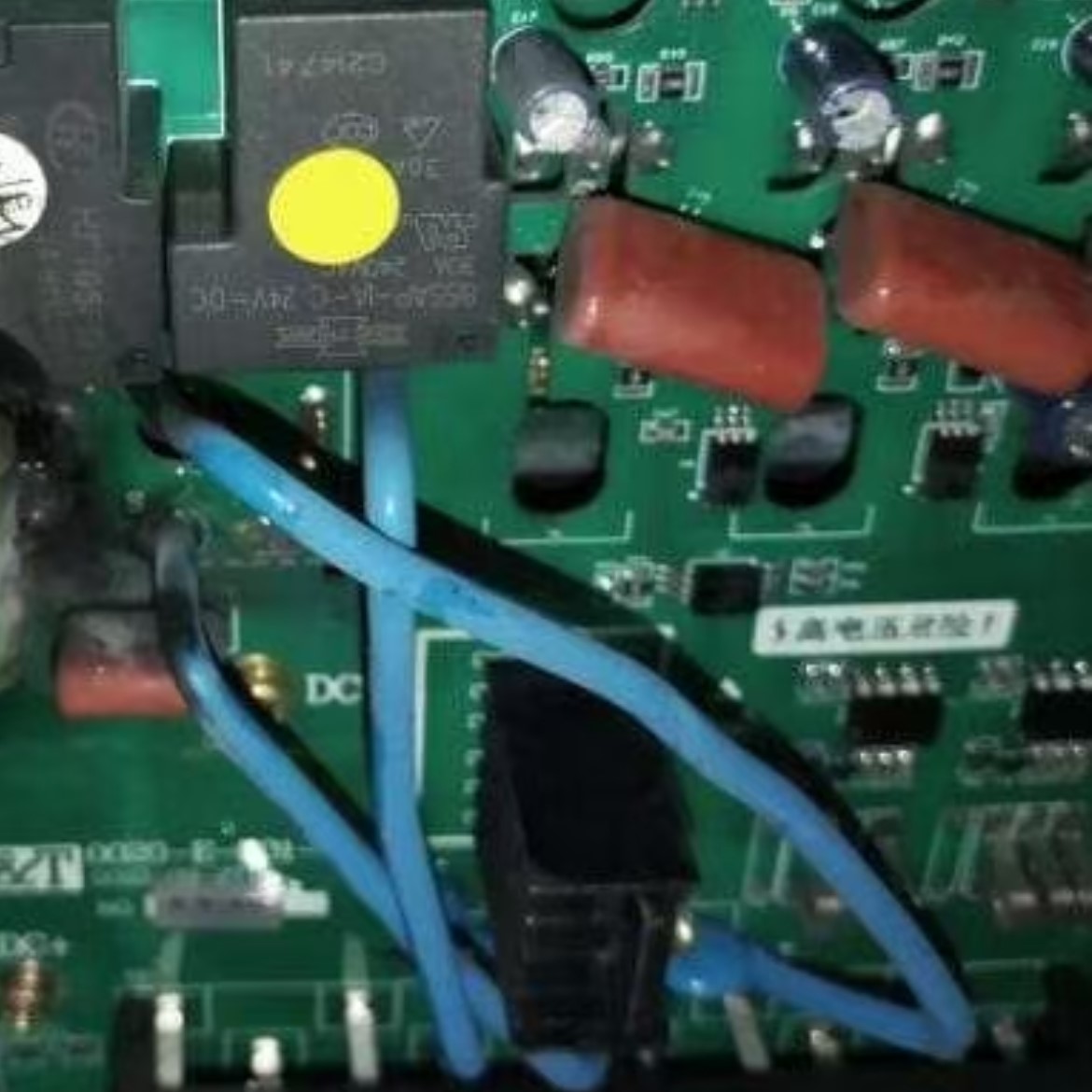

- Checking the Internal

Components of the Frequency Converter:

- Open the frequency converter case and check

whether internal components such as the inverter module, drive circuit,

and current detection circuit are damaged or aged. If there are damage or

aging phenomena, relevant components need to be replaced in time26.

By following these methods, the OC fault of the

frequency converter can be effectively resolved, ensuring its stable operation.

What is the OV fault in a frequency converter?

The OV fault in a frequencyconverter refers to an over-voltage fault.

OV stands

for Over Voltage, indicating that the input voltage of the frequency converter

exceeds its rated value. This fault is usually related to excessively high

supply voltage or internal faults of the frequency converter. Specifically,

excessively high supply voltage may be caused by abnormal grid voltage or

transformer failure; while internal faults of the frequency converter may involve

the failure of over-voltage protection circuits or rectifier bridges and other

components. In addition, the specific causes of OV faults may vary among

different brands of frequency converters. For example, an OV fault in an jienlu frequency converter may be caused by

expired battery life, triggered overload protection, damaged power

transformers, circuit board failures, or other factors such as overall machine

aging. On the other hand, an OV fault code in a Delta frequency converter may

be caused by excessively high supply voltage, improper internal parameter

settings of the frequency converter, sudden load changes, motor failures, and

other reasons. When dealing with an OV fault in a frequency converter, it is

first necessary to check whether the supply voltage is stable and meets the

input requirements of the frequency converter. Then, check whether the internal

parameter settings of the frequency converter are correct, and also pay

attention to the load condition and whether the motor has failed. Through

careful troubleshooting and repairs, the frequency converter can be restored to

normal operation.

What are the solutions to the OV fault in a frequency converter?

The solutions to the OV fault in a frequency converter

mainly include checking the supply voltage, adjusting the deceleration time,

monitoring load changes, checking for internal equipment faults, and repairing

or replacing faulty components.

- Checking the Supply

Voltage:

- Use a multimeter to measure the input supply

voltage and ensure it is within the specified voltage range of the

frequency converter.

- If the supply voltage is too high, consider

installing a voltage stabilizer to stabilize the voltage or consult with

the power supply department to resolve voltage fluctuation issues12.

- Adjusting the

Deceleration Time:

- During the deceleration process of the

frequency converter, if the deceleration time is set too short, it may

lead to an overvoltage fault. Therefore, based on the inertia of the load

and actual operating conditions, appropriately extend the deceleration

time13.

- Monitoring Load

Changes:

- Sudden load changes can cause abrupt changes in

motor speed, resulting in overvoltage. Therefore, for situations where

load changes may occur, additional monitoring devices for load changes

can be added or corresponding control measures can be taken1.

- Checking for Internal

Equipment Faults:

- Check whether the voltage detection circuit of

the frequency converter has failed, such as damage to the voltage sensor

or changes in the detection resistance value.

- Inspect the power supply section of the

frequency converter for damaged components, such as capacitors and

resistors15.

- Repairing or

Replacing Faulty Components:

- If faults are found in the voltage detection

circuit or other components, repairs or replacements should be carried

out.

- If none of the above methods resolve the issue,

consider replacing the frequency converter itself15.

During the repair process, safety precautions must be taken. Turn off the power, wear professional protective equipment, and avoid dangers such as electric shock. Additionally, avoid arbitrarily dismantling internal components of the frequency converter to prevent causing greater damage.

Products related to my wastewater treatment system