Common Causes of Inverter Failures

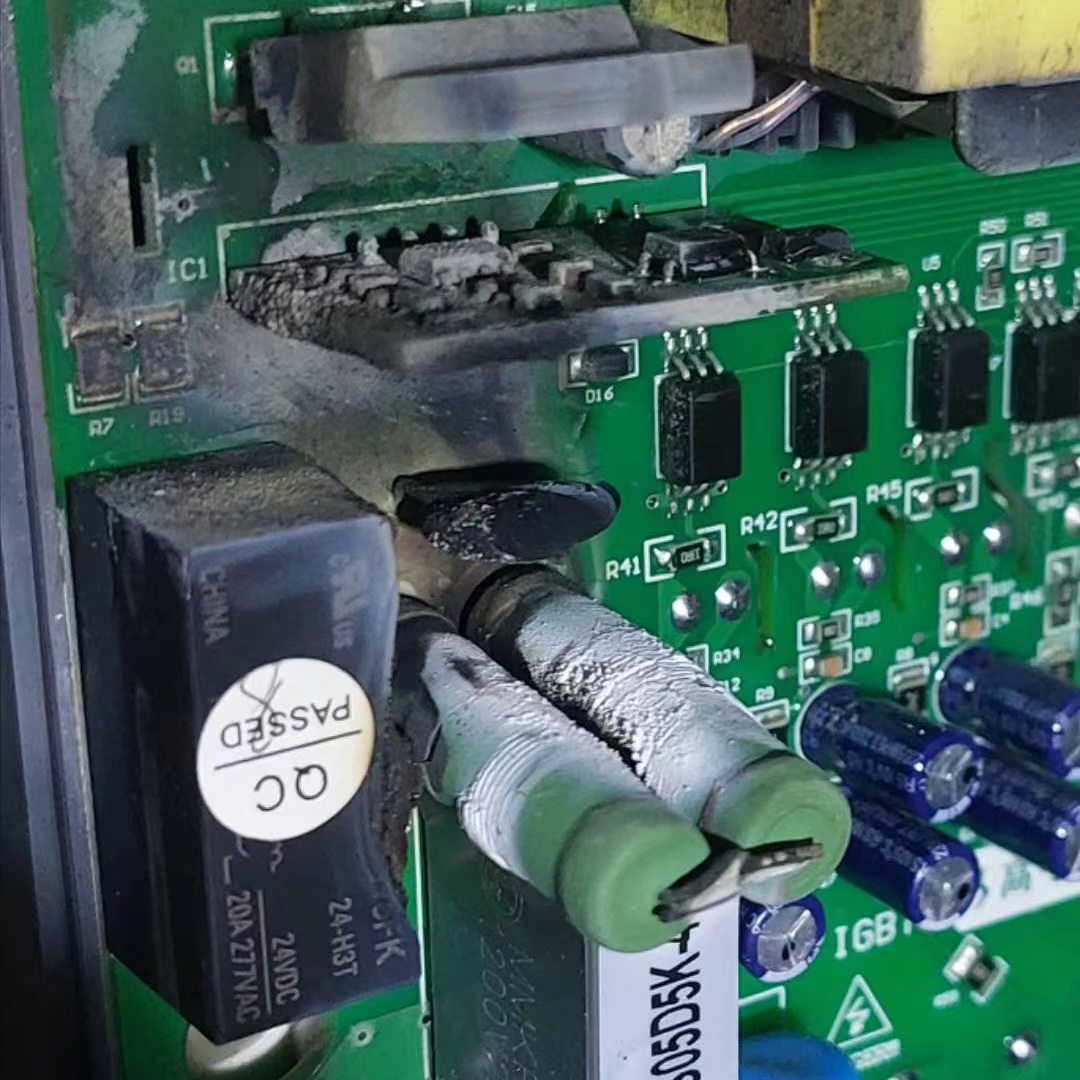

I am not a design engineer, but as a

quality management professional, I would like to outline some major causes of

inverter failures that I’ve encountered:

1. Lack of Phase Loss or Overvoltage

Protection: If the circuit design of a three-phase inverter does not take into

account input phase loss protection or overvoltage protection, the inverter can

easily get damaged during operation.

2. Improper Circuit Design: Poor circuit

design is another key reason why inverters are prone to failure.

3. Component Selection in the Early

Development Stage: The selection of all electronic components during the design

and development stage is crucial. The technical confirmation of all components

before production is especially important.

4. Temperature Control in Soldering

Processes: Temperature control during reflow soldering, wave soldering, and

manual soldering of components is critical. Components that suffer heat damage

may not show faults during factory testing but could have a shortened lifespan

or fail under high current and voltage conditions once they are in the market.

In summary, aside from failures caused by

static electricity, factors such as circuit design integrity, component

selection, and temperature control during soldering are major contributors to

inverter failures under high current and voltage conditions.